What’s the secret to running a highly efficient and effective ventilation system? Naturally, you’ll need an ultra-efficient Energy Recovery Ventilator (ERV) unit that can accommodate the cubic feet per minute (CFM) air flow rate necessary for the space. However, there’s more to it. That unit needs to be installed as part of a balanced pressure system. We’re talking a set-up where fresh, incoming air must be equal to outgoing, poor quality air. To do that, two fans must complement your ERV unit to help balance the airflow against static pressure. But how do you choose the correct fans?

Step One: Be sure your ERV meets the Outdoor Air Requirements for your space.

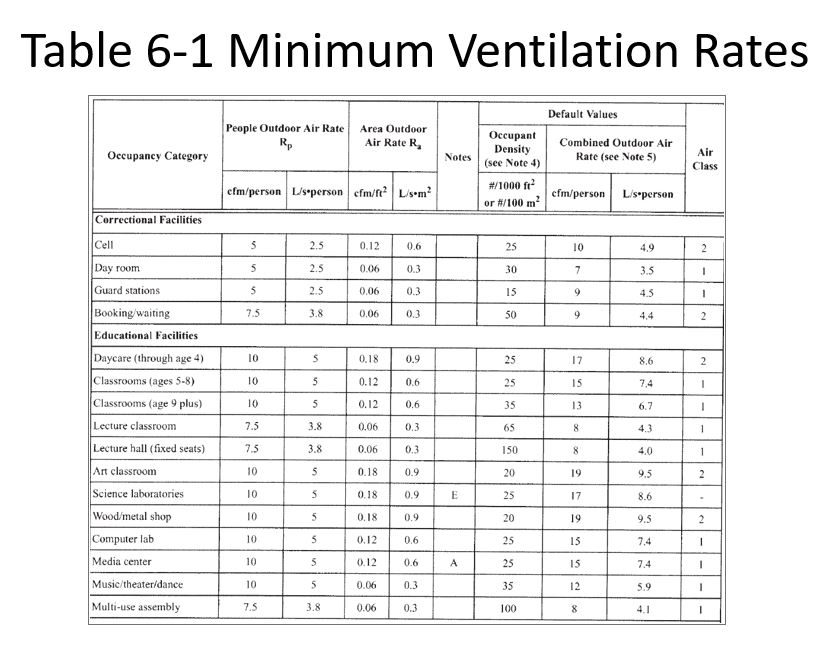

Choose the correct ERV by determining the cubic feet per minute (cfm) or minimum ventilation rate required. Using the floor area for the space and the typical number of occupants, reference ASHRAE Standard 62.1 Table 6-1 Minimum Ventilation Rates to plug in the numbers as follows:

This is the formula in action for a hypothetical lecture classroom with a floor area of 2,000 sq.ft.

MVR (CFM) = (cfm per person x # occupants) + (cfm per sq.ft. x floor area)

CFM = (7.5 x 20) + (0.06 x 2,000 sq.ft.)

CFM = 150 + 120

CFM = 270

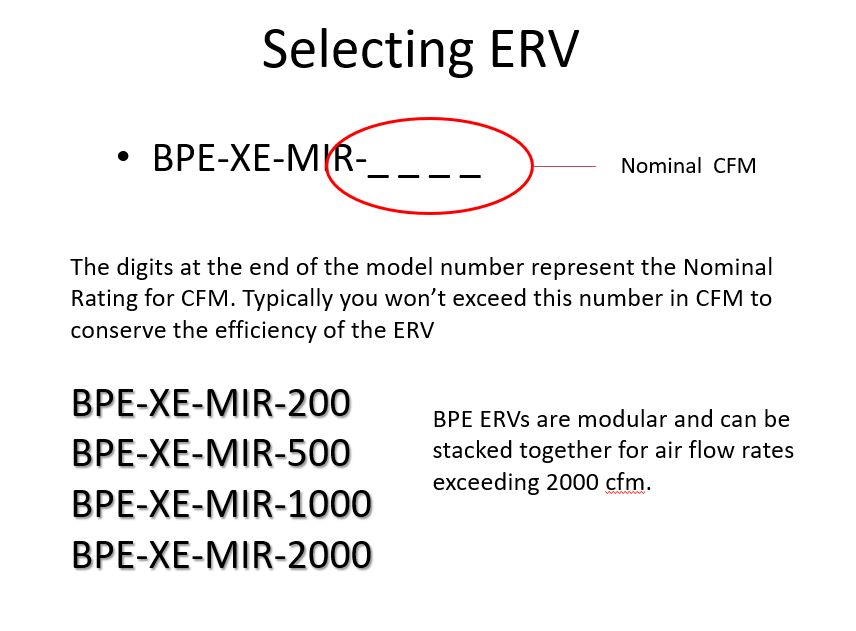

Now we can select an ERV unit perfect for the job:

In our classroom example, we would choose the BPE-XE-MIR-500, because the 200 model would fall a bit short of our Minimum Ventilation Rate goals.

Step Two: Understand How to Battle Static Pressure

Ductwork is notorious for creating static pressure that, left unchecked, can unbalance a system. Static pressure is typically measured by a pressure gauge (called a manometer) in ‘inches of water gauge (wg)’ or the amount of static pressure needed to suck one inch of water into the first inch of a straw. The concept behind static pressure is simply a matter of physics: It is the result of total pressure drop or negative pressure that the air butts up against on its way through a building’s HVAC system. The moment air enters the ERV it faces the pressure drop incurred by the ERV itself. Then it’s an uphill battle against filters as well as the distance, design, and surface material of the ventilation system’s duct work. Proper fans will assist air in navigating the static pressure that is naturally present in all ventilation systems.

Engineering Tips for Controlling Static Pressure:

- Add two-speed controllers, one for each fan, to make up for unexpected static pressure resulting from ductwork and/or dirty filter issues. Individual fan controls also allow for free cooling and full adjustment capability during winter or summer operations.

- When adding intake filters, ductwork bends, and supply/return registers, choose larger connections. For example, going from a 6-inch round connection to a 10-inch alternative will cost the same but incur 1/10 the static pressure! Cutting overall static pressure can drop fan power by 75%. Since fan laws are exponential, just cutting the static pressure in half will cut system operating costs 75% for the life of the ventilation system! Simple payback for upgrading the ductwork and reducing the system back pressure will have a payback schedule of under a year! It’s a better deal than the stock market can offer you during the next 20-plus years.

Step Three: Choose the right fan for the job!

In Goldilocks style, a fan that is too powerful or too weak promotes an unbalanced system. You want to find a product that’s just right. What happens when your ventilation system is not balanced? If the air pressure throughout the system is too heavy (due to a fan that is too powerful), we have positive air pressure that can promote too much humidity and condensation, resulting in mold and rot, and a possible breeze throughout the space. We could also allow too much heat to escape from the building, wasting all the wonderful potential to recover and use it efficiently. However, without a powerful enough fan, we wind up with negative air pressure, where not enough incoming air is conditioned. This situation can also lead to mold and higher energy costs instead of the money-saving results desired.

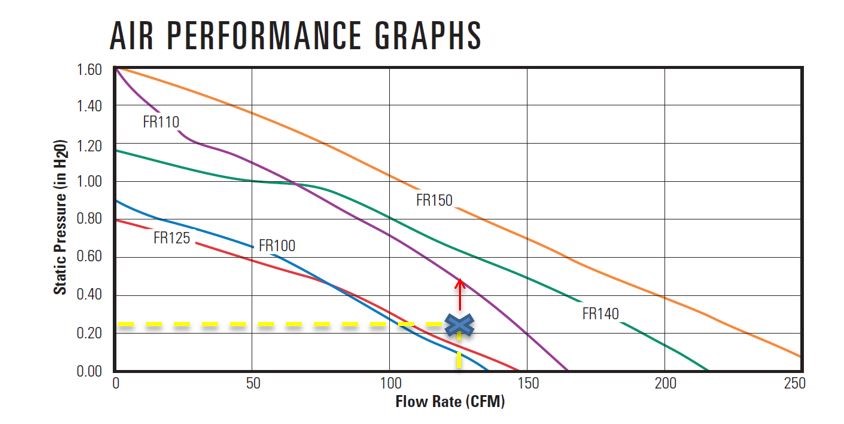

So how do we select the right fans for the job? We refer to a manufacturer’s Fan Curve Performance Table like the one below from Fantech:

Static pressure must be compared with the required air flow rate (CFM) by finding the point where they intersect on the table. Any fan model on the curve above the point where they meet can be used. However, the model closest to that point will be the most efficient. For example, if it has been determined that a space needs an air flow rate of 125 CFM and static pressure measures .25 wg, the two points intersect just above the curve for Fantech’s FR125 model.

Determining which fans accommodate your ventilation system best isn’t difficult. The Haglid Engineering staff can design an effective, balanced, and highly efficient ERV and fan setup. Also, we truly enjoy running fan and ERV schedules! Give us a call at 201.722.1414.