Why meet the HVAC-related requirements of the WELL Building Standard?

Many people think of energy-efficient savings first when planning to meet ENERGYSTAR®, LEED, or Passive House Institute standards and consider health benefits an added extra. However, as we said in a recent article on The International WELL Building Institute’s WELL Building Standard, buildings without superior ventilation contribute to sluggish performance, less astute thinking, and more sick days. In other words, they can be the culprit in poor human energy efficiency. At Haglid EngineeringTM, we believe changing ventilation practices and procedures to improve breathing environments is just as important as lower energy bills, if not more so.

Many people think of energy-efficient savings first when planning to meet ENERGYSTAR®, LEED, or Passive House Institute standards and consider health benefits an added extra. However, as we said in a recent article on The International WELL Building Institute’s WELL Building Standard, buildings without superior ventilation contribute to sluggish performance, less astute thinking, and more sick days. In other words, they can be the culprit in poor human energy efficiency. At Haglid EngineeringTM, we believe changing ventilation practices and procedures to improve breathing environments is just as important as lower energy bills, if not more so.

Key Concepts in Occupant Health. The WELL Building Standard covers ten concepts (Air, Water, Nourishment, Light, Movement, Thermal Comfort, Sound, Materials, Mind, and Community) which all deserve attention. Where to start? If we’re going to improve the quality of occupant breathing, Air and Thermal Comfort are key. Why? Air because there is nothing more essential to life than breathing and Thermal Comfort because uncomfortable people don’t work as well.

Air. Ventilation and air filtration adjustments are critical for meeting the standard’s Air Concept requirements. After all, people breath over 15,000 liters (530 ft3) of the stuff each day.

To fulfill the goal of healthy air in a building, the WELL Building standard seeks to “ensure high levels of indoor air quality across a building’s lifetime through diverse strategies that include source elimination or reduction, active and passive building design and operation strategies and human behavior interventions.”

Using specific reporting tools that include performance testing, documents, photographic evidence, and reports by architects, contractors, etc., the Standard seeks proof that requirements such as the following are met (sampling):

- Fundamental Air Quality (Meeting thresholds for particulate matter and gasses such as radon)

- Smoke-Free Environment

- Management of Construction Pollution

- Enhanced Air Quality and Ventilation

- Operable Windows

- Active VOC Control

- Microbe and Mold Control

Thermal Comfort. The Standard’s goal in creating Thermal Comfort requirements is to “promote human productivity and ensure a maximum level of thermal comfort among all building users through improved HVAC system design and control and by meeting individual thermal preferences.

Here, too, the Standard relies on reporting tools to confirm improvements in the following areas are met (sampling):

- Thermal Performance (in meeting

- Enhanced Thermal Performance (The WELL Building Standard seeks maximum levels of thermal comfort.)

- Thermal Zoning

- Thermal Comfort Monitoring

- Humidity Control

Creating superior indoor air quality and optimizing thermal comfort in a commercial building or home makes sense regardless of the certification standards you choose to meet. What many people don’t understand is that the effort involved doesn’t have to be a daunting task. A superior Energy Recovery Ventilator added to your HVAC system—and in some cases as a replacement of your HVAC system—can help meet WELL, ENERGYSTAR®, LEED, or Passive House Institute standards.

Will any ERV do? Not if you want to optimize your ventilation and thermal comfort. Standard ERVs need additional heating or cooling to precondition air and may sit at 38% to 55% thermal efficiency. Static pressure (the resistance air meets while traveling throughout an HVAC system) can run high (up to 2 in. wc.) and result in the unit having to work harder to move air through ductwork. The situation can compromise efficiency and can lead to higher levels of heat or cold than desired. In the end, your Energy Efficiency Rating (EER) or BTUs per watt of power will reflect the performance of the unit. Standard ERVs tend to test at EERs of 10.

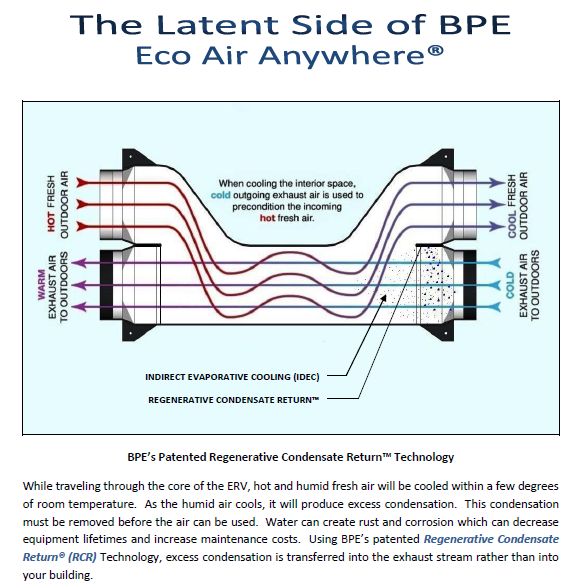

What makes an ERV superior in performance? Building Performance Equipment (BPE, Inc.) does. Thanks to uniquely-engineered, patented solutions, a BPE Energy Recovery Module can run at well over 90% thermal efficiency. Static pressure tends to be very low (.5 in. wc.) thanks to the linear flow path of a true direct-counterflow design. As a result of all this and more, BPE units boast high EERs, sometimes in excess of 126! And remember that WELL Standard requirement for humidity control? BPE’s patented Regenerative Condensate ReturnTM technology has that covered, too

There is no question about whether BPE modules can help you reach your energy efficient certification needs. However, you might have questions about how to size and design the best system for your space. BPE recognizes that, as the benefits to building, owning, and living in healthier spaces become obvious to more people, it’s important to have equipment on the market that makes adaptation easy, affordable through fast ROIs, and markedly effective. Tell us your goals and lend us an ear! BPE, Inc. can help you understand the ins and outs of truly superior ventilation.