Vent your problems--properly!

While the results of salon treatments may be easy on the eyes, the air in many beauty and nail salons is often filled with downright ugly chemicals that venture into your lungs and become rather hard on the body. When you consider people process up to 60 lbs. of air in eight hours, you start to wonder how great that new coif or those glossy nails look on the inside of frequent patrons. Now imagine the exposure for salon employees exposed to harsh chemicals and particles forty hours a week. And all that was before we had to worry about a virus. Last we checked, your local beautician wasn’t sporting six-foot long arms. While the dangers are concerns for anyone visiting a salon, those hanging around the place all day are, of course, most at risk.

While some salon owners, employees, and clients dismiss pleasant and obnoxious odors as unavoidable givens, the dangers have not gone unnoticed by the EPA and groups such as Women’s Voices for the Earth. HVAC professionals also warn of the dangers. In fact, if you look at Table 6-1 of ASHRAE standard 62.1, you’ll find a minimum ventilation rate of 20 cfm for beauty and nail salons compared to 5-10 cfm for most other indoor environments.

Culprits in poor salon indoor air quality

Not all salon odors pose health concerns and some vapors and particles you can’t smell may be among the worst chemical culprits. Hair products such as curling and straightening solutions, dyes, and bleach are concerns. Then there are chemical peels, waxes, disinfectants, cleaning products, nail polishes, acrylics, gels, hardeners, and removers. When you get right down to it, salons are practically chemical factories when care isn’t taken to ventilate the space properly.

The Chemicals: Cosmetologists risk neurological issues, respiratory issues, skin conditions, and cancer when regularly exposed to volatile organic compounds (VOCs) such as formaldehyde, toluene, xylene, dibutyl phthalate, and acetone. The chemicals find their way into the lungs and/or enter the body through skin. Solvents can strip away the natural oils on skin and dry it out, making it easier for chemicals to leech into the body. Dust and particles such as those from nail filings also carry chemicals into the mouth, nose, and eyes. While the EPA does advise workers to wear dust masks in its guide, Protecting the Health of Nail Salon Workers, they admit the protection only goes so far since chemical vapors can still pass through.

Solutions for creating a healthy beauty salon environment

Fortunately, concern over the health of salon workers is growing along with the knowledge that high-quality air is feasible in cosmetology environments. Initiatives to address poor nail salon air quality are popping up over the last couple of years. For example, California’s Asian Health Services received a grant from the EPA to launch the Healthy Nail Salon Collaborative program in Oakland, which will help existing salons to install indoor air ventilation equipment, purchase less toxic nail polish, and provide training for nail salon workers.

OSHA says, “Ventilation is the best way to lower the level of chemicals in a salon!” We couldn’t agree more. Lucky for salon workers in New York, in 2016, Governor Cuomo began requiring nail salons to meet ventilation standards set by the 2015 International Mechanical Code. Among other parameters, the code requires mechanical ventilation to expel all exhaust air from the nail salon in a manner that assures no part of the exhaust air recirculates or transfers into the salon or another space in the building. As well, it must operate in a balanced manner where outdoor air is supplied at a rate equal to the rate of exhaust.

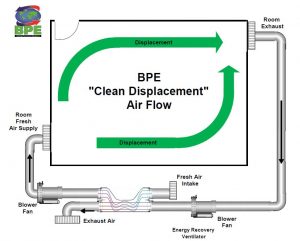

At Haglid Engineering, LLC and BPE, Inc., we feel salon spaces are a perfect example of the importance of implementing displacement ventilation via a high-efficiency energy recovery ventilator (ERV) versus dilution ventilation. Displacement ventilation brings fresh air into a building and pushes the exhaust out the other side rather than simply adding and scattering it. At BPE, we prefer a displacement strategy comprised of good ventilation design and powered by an ERV to keep air moving. We call it BPE ‘Clean Displacement’.

IMAGE: BPE, Inc.

Imagine a shelf full of books. If we continuously push new books onto the left side of the shelf until each book to the right of it has fallen off the opposite side, we end up with a whole new set of books in short order. It’s a simple, ‘clean sweep’ systematic approach–which is exactly what you want when clearing a space of unhealthy toxins. To achieve this optimal displacement of stale or chemical-laden air, an ERV system’s flow must be balanced on the way in and out. Although, Haglid Engineering recommends keeping the pressure of a space where chemicals are used slightly negative to avoid passing chemical odors to the neighbors.

In a nutshell, BPE ERV units … from our BPE-XE-MIR-200-i all the way up to our industrial modular units … excel at bringing outdoor air indoors to displace the air folks have been breathing into around you. And because our true direct counter-flow, Air-to-Air heat exchangers allow virtually no mixing of incoming and outgoing air (less that 1% crossover), you’ll know your indoor air is routinely refreshed … not recirculated.

As if providing clean air in a space where workers use toxic products isn’t enough of a reason to install a BPE ERV, here are more advantages:

- ERVs precondition outdoor air to a comfortable room temperature by recovering heat energy from exhaust. The recovered energy is used to warm incoming fresh air in colder months and cool it during the warmer months.

- A BPE ERV will provide comfortable humidity levels thanks to a versatile allowance for low pressure drops as well as high-heat and high-moisture transfer.The secret is our patented Regenerative Condensate Return® technology. Especially key during these times, it keeps relative humidity levels in range (40% to 60%) for minimizing proliferation of the COVID-19 virus.

- Energy bills are lowered substantially thanks to our BPE engineering. You can run a unit using less power than an incandescent light bulb. How? BPE ERVs are super-efficient, air-to-air, direct counter-flow units that typically run 80% thermally efficient on up to 98% and have an Energy Efficiency Rating (EER) that is unsurpassed at between 36 and 160 EER. (10 EER is typical of the industry.) Our units have helped Haglid Engineering turn a gas-guzzling 656,000 sq. ft. warehouse/office complex into a net-zero power producing gem in New Jersey’s building stock. So, creating a pristine breathing environment in a salon is cake.

- When your HVAC system is run in this manner, the reduced power reduces your carbon footprint.

Chemical-laden and high-odor indoor environments are best served by eliminating the cause as quickly and efficiently as possible. When you add Covid-19 to the mix, it’s important to re-open in the best manner possible to increase the chances of staying open. Why not use a method that provides a superb return on investment as it relates to health, finances, and your status as a more sustainable business? To discover the best mechanical ventilation system for your space, give us a call at BPE, Inc.!