Installing spiral (round, tubular) ductwork throughout your HVAC system is like discovering that awesome health supplement guaranteed to cure a slew of ills—except tubular ductwork lives up to the hype. Choosing it over rectangular ductwork for medium- and high-pressure systems results in practical, healthy, aesthetic, and financial advantages. In fact, ASHRAE recommends spiral ductwork be used wherever possible.

Spiral ductwork is practical.

Spiral ductwork can make system builds quicker and easier. Because it is available in longer lengths than rectangular ductwork, installation requires fewer connectors and joints. Its lock-seam construction provides rigid strength that doesn’t rely on hangers and stiffeners. Such strength allows for lighter gauges that ease lifting and placement. Plus, an installer can often get away with using a drill and screws instead of fussing with caulk, gaskets, cleats, and field cuts.

Maintenance becomes easier, too. When running performance checks, you need fewer holes for airflow and CF2 sensors than with rectangular ducts. With no corners and inner edges, spiral ducts harbor little dust and debris, but when cleaning is necessary, spinning brushes do the job nicely. You’ll also see less water damage on roof-mounted spiral ducts since water rolls off rather than collects in the nooks and crannies of rectangular ductwork and its mountings.

Promote health with spiral ductwork.

Spiral ducts offer airtight passage for incoming and outgoing air over less inner surface area. While there are many advantages to such airflow, healthier indoor air quality is most important. The smoother passage discourages grime and pathogens from collecting inside the duct, thus preventing bacterial growth in the tubes that can hitch a ride on an airstream. Also, rectangular ductwork tends to need more connectors and sealants that can outgas toxic VOCs.

Make way for sleek and silent air passage.

Most folks would agree rectangular ducts look clunkier than spiral. Since tubing is sleeker, many architects and designers prefer the aesthetic. Especially useful for long runs with fewer connectors, spiral ducts look great in spaces such as arenas, gyms, and industrial shops.

Spiral ducts sound great, too. As in, you don’t hear them much. The circular inner surface creates equalized air pressure as opposed to the pressure differentials encountered with rectangular ducts. That equalized pressure discourages breakout noise.

Spiral ductwork raises HVAC efficiency and lowers operating expenses.

From the start, spiral ductwork can cost up to 50% less than rectangular to install (37% on average). The savings don’t end there. Thanks to their shape and equalized internal pressure, spiral ducts process airflow with lower pressure drops. When those lower pressure drops encourage even and efficient flow, your energy bill goes down. Bonus: When your system isn’t fighting much pressure, you don’t need extra horsepower oomph, so you can purchase smaller (less expensive) equipment.

Spiral ducts have less surface area, limiting heat loss or gain. And if you’re going to wrap it, you’ll need less insulation. Since the tubes are more airtight than rectangular ducts, with fewer seams, temperature control improves as well. Your AC and heating system won’t need to make up for escaping airstreams, more easily maintaining comfort and using less energy to do so.

When is rectangular ductwork a better bet than spiral?

Despite the glories of spiral ducts, there are times when rectangular ducts should be your air passageway of choice. Your contractor will be the judge, but sometimes the height of tubular ducts makes in-wall and tighter applications difficult. The lower profile of rectangular ducts may be an advantage there. Rectangular ducts can be made wider where necessary as well. Also, they still reign for better efficiency in low-pressure systems.

Questions about the best ductwork for your HVAC system? Give us a call to chat about your HVAC needs. We design systems for the smallest home to the largest industrial complex!

Ductwork bends and transitions

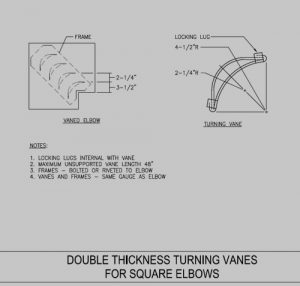

Regardless of the type of ducts you use in an HVAC system, you want to use as few bends and connectors as possible. Sharp corners are the worst of static pressure drop villains, but if you can’t avoid them, install inline vanes. Vanes can drop the static pressure to round a sharp corner by as much as 85% and allow for more even air flow distribution especially when introduced in the inlet of an energy recovery module.

A word of warning: Vanes can cause trouble if not installed properly. Never install them at the entrance to a duct branch because the vane can mess with the airflow coming from the main duct, causing pressure increases. Another caveat: Be certain vanes align with ductwork properly or they’ll create turbulence.

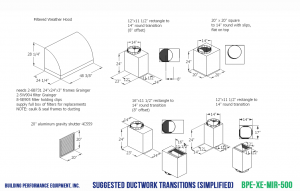

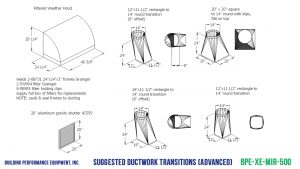

Ductwork Transitions play a role in efficient HVAC performance.

Another area where you can lessen unavoidable static pressure is in your transitions. Less experienced ductwork installers may opt for simplified box transitions, which do the job, of course, but can compromise efficiency.

Instead, install tapered transitions. Not only will they make a system look sleeker, you’ll also lessen the added friction that comes from a change in flow.

For more tips on minimizing static pressure in your HVAC system, give us a call!