Photo by Mys 721tx – Own work, CC BY-SA 3.0

Photo by Mys 721tx – Own work, CC BY-SA 3.0

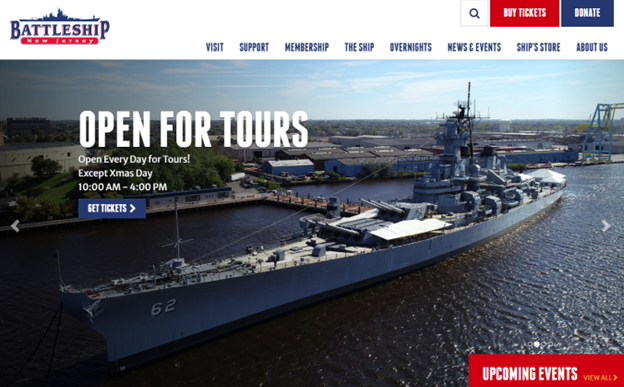

Where does the most decorated warship to serve in the U.S. Navy go to retire? The USS New Jersey, one of the largest battleships of its kind, went out of service in 1991, eventually transitioning into a museum in Camden, NJ by 2001.

Tours began to give the public first-hand experiences in how an Iowa Class ship operates. At over 887’ long, with a full displacement of 57,540 tons and torpedo-proof 18”-thick walls, the behemoth certainly attracts visitors.

Transitioning an operational battleship into a docked building involved switching out some heating and cooling features used at sea. When docked, the boilers and thus, all steam-powered apparatus could not be run. Plus, some areas of the ship in and around engineering were never climate controlled due to the equipment that would have kept throwing off heat no matter what. As a museum, the ship now relies on a boiler based on the pier that pumps through the waterline of the ship. A modern cooling tower sits aft of the second funnel. Today, touring paths are nicely climate controlled.

However, in 2009, when the museum wanted to invite families and groups such as the Boy Scouts to tour the ship complete with ‘encampment’ overnights in the living environment that once housed Navy personnel five levels down, a problem arose. A stinky one originating from the space’s head area (bathrooms). In a space meant to hold 300 people, the issue could make for along night!

However, in 2009, when the museum wanted to invite families and groups such as the Boy Scouts to tour the ship complete with ‘encampment’ overnights in the living environment that once housed Navy personnel five levels down, a problem arose. A stinky one originating from the space’s head area (bathrooms). In a space meant to hold 300 people, the issue could make for along night!

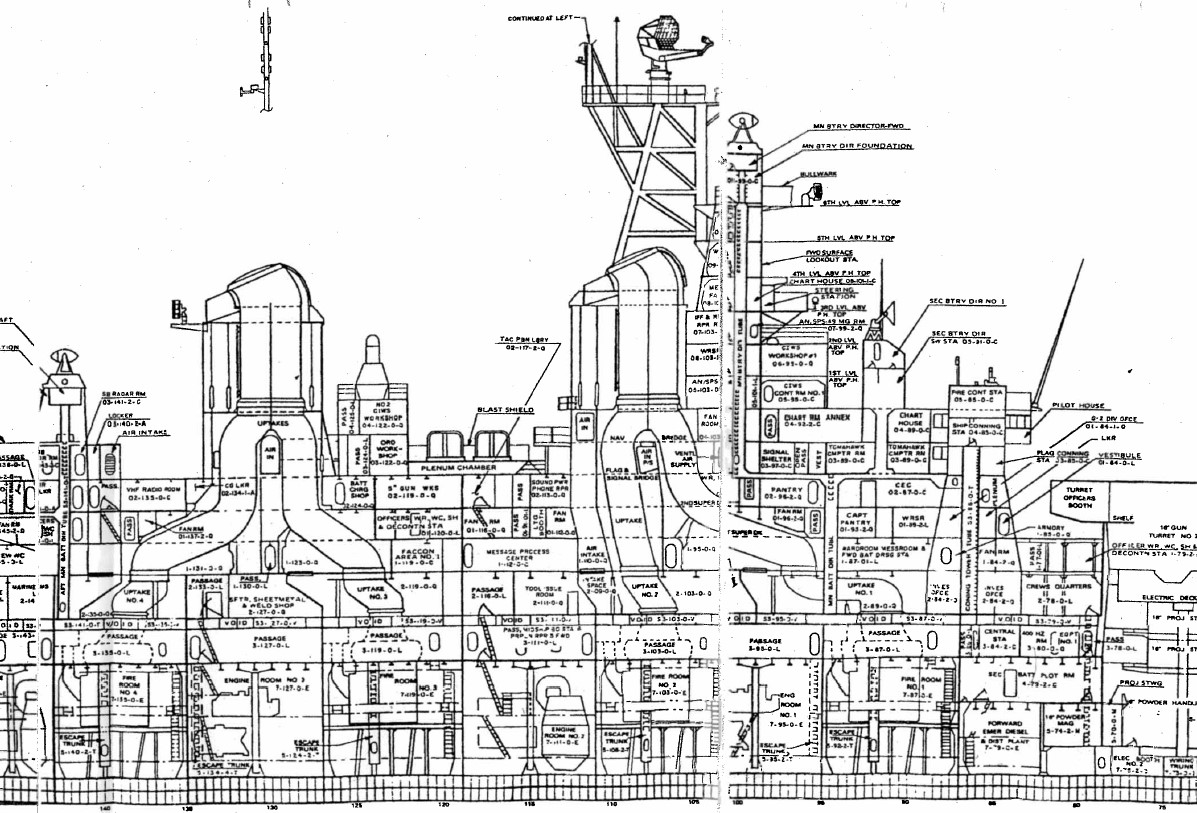

Upon investigation, BPE CEO, Klas Haglid, P.E., R.A, found places inside the head area to pull fresh air in through an intake and precondition it with exhaust air using five floors of previously dead ductwork, one BPE-XE-MIR-200 ERV, and two in-line, high-efficiency Fantech FR100 fans. The total power consumption of the fans would be only 38 watts of power. Using the old ductwork and repurposing a heavily armored 2”-thick fresh air intake are examples of BPE’s belief in retrofitting as cost-effectively as possible.

Upon investigation, BPE CEO, Klas Haglid, P.E., R.A, found places inside the head area to pull fresh air in through an intake and precondition it with exhaust air using five floors of previously dead ductwork, one BPE-XE-MIR-200 ERV, and two in-line, high-efficiency Fantech FR100 fans. The total power consumption of the fans would be only 38 watts of power. Using the old ductwork and repurposing a heavily armored 2”-thick fresh air intake are examples of BPE’s belief in retrofitting as cost-effectively as possible.

Due to the non-profit funding issues that plague many museums, Haglid donated the 200 unit– the World’s longest and most efficient direct counter-flow energy recovery system–and the fans. The system provides thermal comfort, improves air quality–and of further importance to a non-profit entity–saves energy.

Due to the non-profit funding issues that plague many museums, Haglid donated the 200 unit– the World’s longest and most efficient direct counter-flow energy recovery system–and the fans. The system provides thermal comfort, improves air quality–and of further importance to a non-profit entity–saves energy.

And what did Klas Haglid get out of the deal apart from sharing his patented energy recovery technology? Plenty! For starters, he got to tour the ship with his son. As an extremely involved dad who enjoys sharing interests with his kids, Haglid has taken karate classes and sparred with them and built bulls-eye boards for practicing with throwing stars. So, sharing the tour with young Hunter, quite fascinated with ships back then, became an adventure neither would forget. When his son asked if they could take the ‘boat’ out for a ride up and down the river, discovering that the museum was no longer going anywhere was soon forgotten as they went behind the scenes to points of interest not shown on tours. Highlights included:

technology? Plenty! For starters, he got to tour the ship with his son. As an extremely involved dad who enjoys sharing interests with his kids, Haglid has taken karate classes and sparred with them and built bulls-eye boards for practicing with throwing stars. So, sharing the tour with young Hunter, quite fascinated with ships back then, became an adventure neither would forget. When his son asked if they could take the ‘boat’ out for a ride up and down the river, discovering that the museum was no longer going anywhere was soon forgotten as they went behind the scenes to points of interest not shown on tours. Highlights included:

Left: mechanical fire control room; right: axial helm

The mechanical fire control room with its calculator for precision in aiming the canons was state of the art 60 years ago. Today, a hand-held digital calculator would make short work of the firing angles.

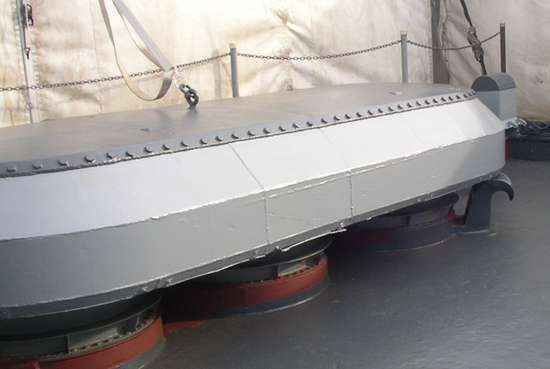

Solid brass and metal work at the axial helm deep in the body of the ship impressed Haglid. It left no doubt that the USS New Jersey was built as a work of art made for war and the worst weather the oceans could throw at it.

Solid brass and metal work at the axial helm deep in the body of the ship impressed Haglid. It left no doubt that the USS New Jersey was built as a work of art made for war and the worst weather the oceans could throw at it.

Sailors saluted Haglid at the bow during Fleet Week because … and get this: He became the vessel’s commander for a year!

Best of all, Haglid had the satisfaction of helping an important piece of history stay relevant and educational to thousands of young people. In fact, everyone at BPE was super proud of being involved with this great floating museum!