Challenge: When a group of Carmelite monks in Wyoming needed more living space, they reduced costs on building a stone European Gothic monastery by carving and installing the limestone and sandstone themselves. The learning curve and time commitment for learning everything from excavation to stonemasonry, CAM (Computer Aided Manufacturing) programming, 3D modeling, and CNC (Computer Numerical Control) operation makes their continuing commitment to finish the project impressive indeed.

Also impressive? The amount of humidity CNC systems create in a room while cutting stone. Powered by a high-pressure water pump, the machines cut through the stone using high-speed water jets. Failing to control excess moisture in the air, especially in summer, creates condensation when the dewpoint gets high enough. Before long, you have machinery prone to corrosion, oxidation, and electrical shorts as well as the cost of replacing parts.

Comfort was another issue. The ventilation solution they sought would also need to warm Wyoming’s winter air—sometimes as frigid as -20 degrees—as it enters the stone carving facility.

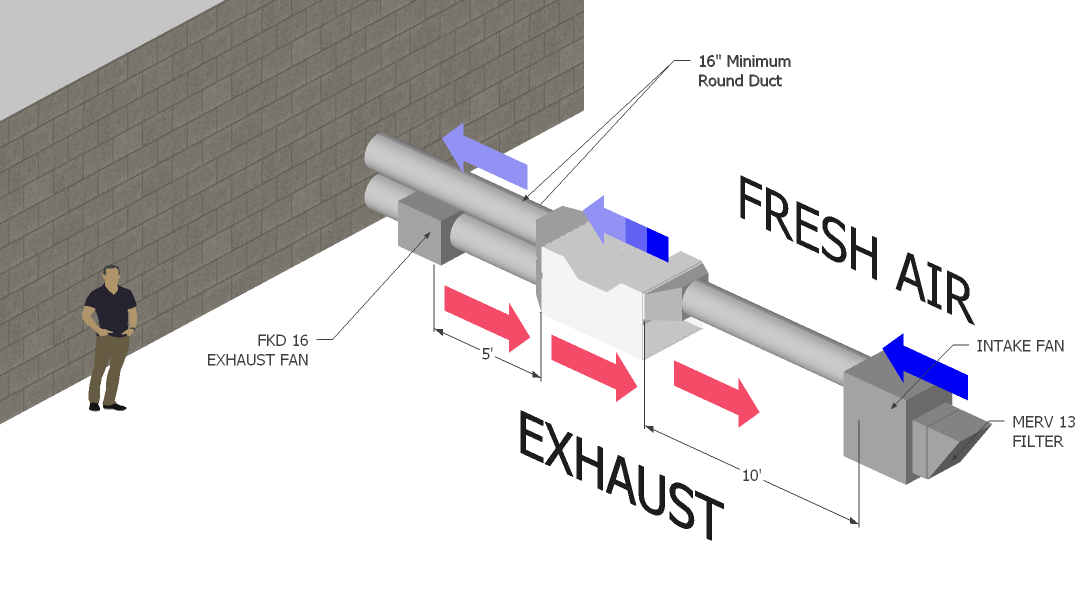

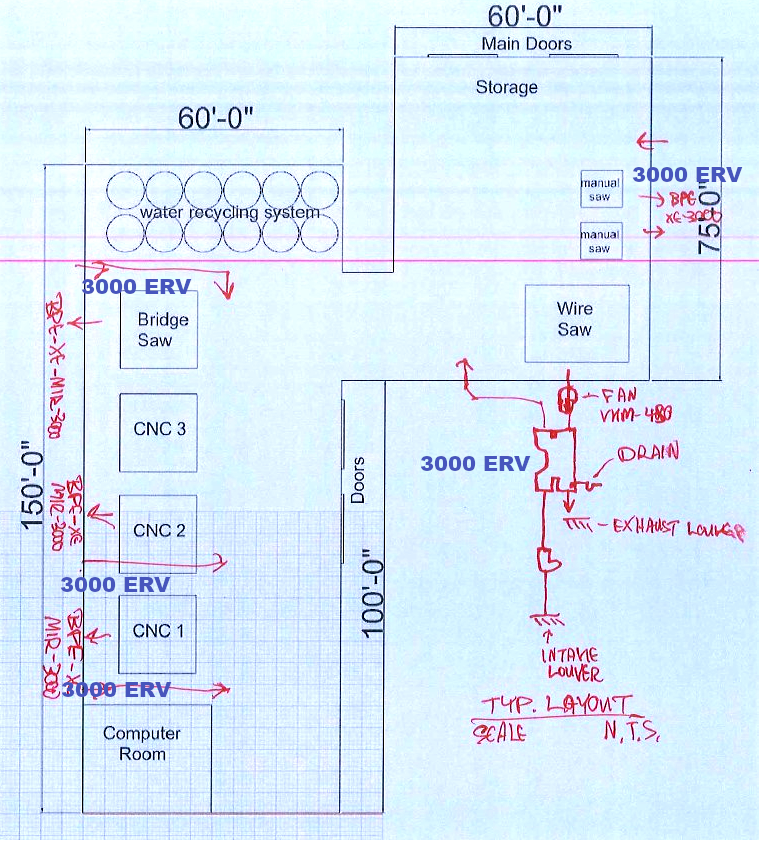

Above, the layout for installing the ERV units. Below, fresh air—whether cold or warm—is brought into the building by the ERVs at a comfortable temperature thanks to BPE’s high thermal efficiency.