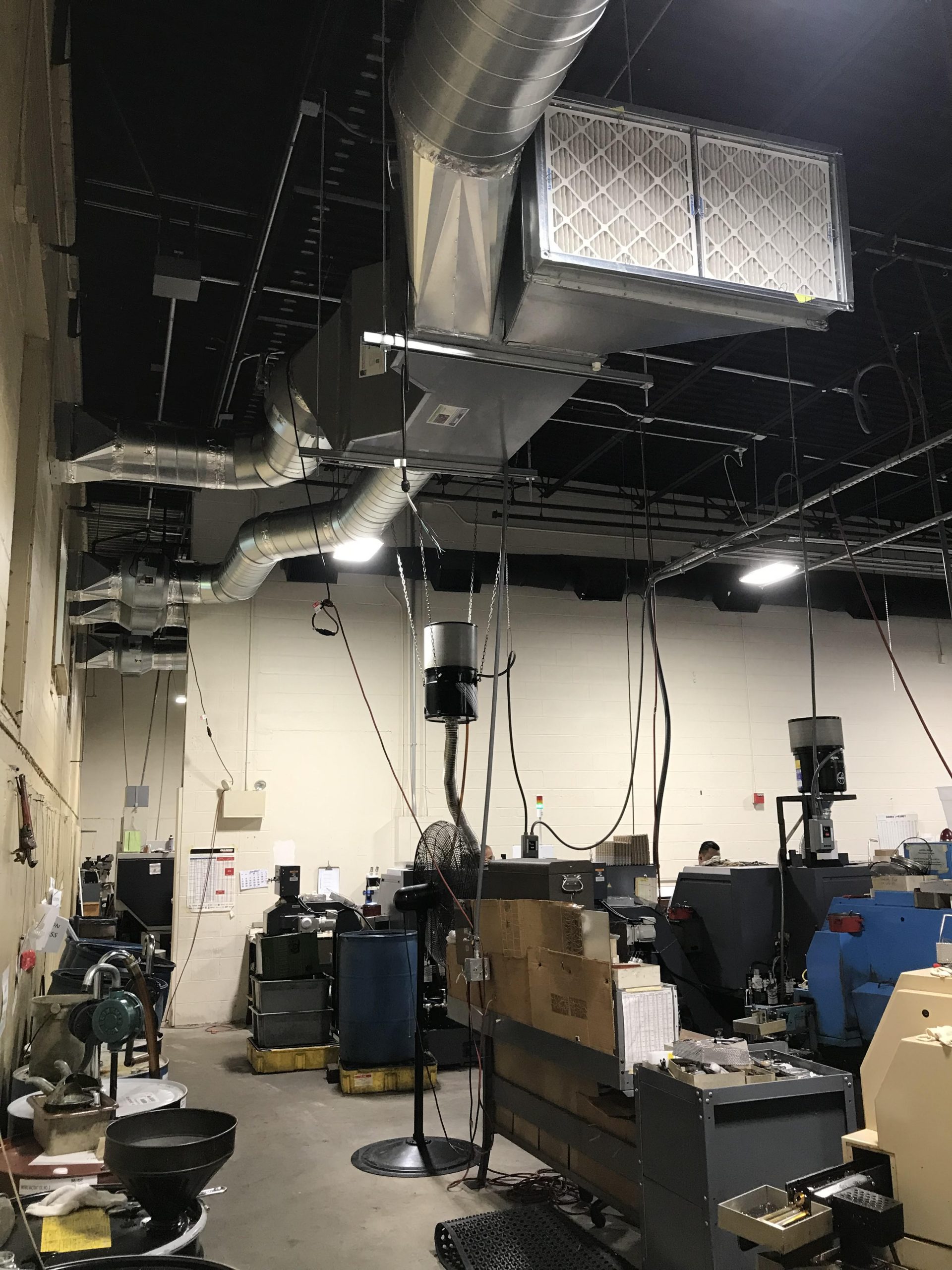

Challenge: When fresh air exchange is poor, machine shops are known for exposing occupants to chemicals, oils, solvents, hotter ambient air temperatures, and sometimes humidity. This typical screw machine shop turns long bars into custom parts. The oil-based coolants necessary for running the machines exposed employees’ senses to oily, heavy, stagnant air—to the point where the shop sometimes took on a haze. The smell and discomfort grew worse throughout the day. This shop needed a cost-effective solution for improving air quality and thermal comfort pronto.

Solution: The shop’s management took the problem to Ventilation USA (www.ventusa.com), which specializes in meeting air quality standards for commercial and industrial spaces while working within the existing infrastructure. The company’s president, Richard Egan, quite familiar with Building Performance Equipment, Inc.’s line of energy recovery ventilators, placed two BPE-XE-MIR-3000 units at the heart of their recommended solution.

Using superior thermal efficiency, the BPE ERVs routinely displace chemicals and nauseating smells with outdoor air while producing comfortable temperatures amid the worst of winter or summer weather. And since the BPE product line features patented Regenerative Condensate Return® technology, up to 34% latent effectiveness

promotes high-heat and high-moisture transfer to prevent humidity should it arise.

How well did this solution work to exhaust contaminants? Egan reports that the system is working great and that employees thanked the machine shop owner for providing fresh, comfortable air!